Plasma (“the fourth state of matter”) is an extremely high-temperature, highly ionized gas that is able to carry an electric current. Natural plasma includes lightning and gas at the surface of the sun, while man-made plasma is formed using a plasma torch to pass an electric current through a gas like oxygen. The reaction dissociates the gas into electrons and ions and increases its temperature to nearly as hot as the sun’s surface. This plasma can then be used for plasma gasification, a process that breaks waste down into basic chemicals.

Plasma gasification can turn “any kind of trash” into chemical products and clean fuels. Industry leader InEnTec was founded in 1995 to focus on governments and companies with large amounts of toxic waste. Their patented Plasma Enhanced Melter (PEM) system is deployed in 13 facilities worldwide. “Back in the early ’90s, global warming was more of an academic pursuit,” InEnTech co-founder, president, and CEO Jeffrey E. Surma told MIT News in 2021. With climate change a leading global challenge, his co-founder, Daniel R. Cohn, believes it is time for InEnTech to expand its impact.

“About 130 million tons of waste per year go into landfills in the U.S., and that produces at least 130 million tons of CO2-equivalent emissions,” Cohn argues. Most of these emissions are methane, a greenhouse gas that is 28 times more potent than carbon dioxide (CO2) and a global concern. The Global Methane Initiative (GMI) is an international public-private partnership focused on advancing methane mitigation in oil and gas, biogas, and coal mines. By utilizing plasma gasification and reducing or even eliminating landfills and other waste, the GMI could make significant advancements.

The Westinghouse Plasma Company (WPC), which has developed plasma torch technology for over 30 years, hopes to transform waste management using plasma. Their predecessor, Westinghouse Company, established full-scale facilities in Mihama-Mikata and Utashinai, Japan, in 2002 and 2003. A “next generation” gasifier was established in Pune, India in 2009, which now treats hazardous waste across 40 industries.

Today, WPC aims to expand the use of plasma technology to manage industrial waste, municipal waste, hazardous waste, and more. The plasma torch breaks the waste down into synthesis gas (syngas), a combination of hydrogen (H2), carbon monoxide (CO), CO2, and slag. The slag, a byproduct from heavy metals and inorganic materials, accounts for only ten to twenty percent of the initial waste and can be used in civil construction, and the syngas can be converted into power and biofuels. From there, the biofuels can be used for diesel, jet fuel, and gasoline, and the power can be used for engines and fuel cells. Plasma technology can also be integrated into existing incinerators to treat the ash and turn it into slag.

Integration of plasma gasification technology could have a significant impact on waste. In 2018, the United States generated 292.4 million tons of municipal solid waste (MSW). The U.S. also generated about 600.3 million tons of waste from construction and demolition, resulting in 290 million tons of waste being sent to landfills by the U.S. alone in 2018. According to the World Bank, about 2two billion tons of waste was generated globally in 2018, 70 percent of which was sent to landfills or dumped “in the open.” While not all waste is ideal for plasma gasification, about 80 percent of MSW in landfills is eligible for gasification.

Applications of gasification to municipal waste are not without challenges. Facilities in Europe, Canada, and the U.S. have faced technical challenges such as corrosive damage to equipment, energy inefficiency, and difficulty regulating reactor temperatures. A 2010 report by the German Development Cooperation (GIZ) summarized, “There is no reliable technology readily available. High costs for technical development, repair, and maintenance make it unprofitable. Dangerous threats exist to the environment and health due to carcinogenic waste.”

While syngas can theoretically be sold as a chemical feedstock for energy, it is often contaminated or diluted to be sold. When it is burned, the energy produced is often “little more than that demanded to operate the energy-intensive system.” To address this issue, fossil fuels could be burned with the waste or coal could be burned with the syngas. However, this perpetuates reliance on fossil fuels and could exclude such technologies from sustainable energy subsidies. Others have recommended pre-treating waste to sort out material that produces more slag. However, Hakan Rylander, former President of the International Solid Waste Association (ISWA) and CEO of the South Scania Waste Company, argues that waste is “too heterogeneous to be able to treat in a gasification or pyrolysis process, irrespective of how you pre-treat the waste. It is absolutely not applicable for mixed MSW with today’s technology.”

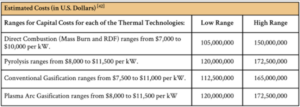

Gasification also presents a heavy financial risk. The cancellation of two gasification projects in 2016 cost the U.S. company Air Products between $900 million and $1 billion. The gasification company Thermoselect in Karlsruhe, Germany, lost over $500 million in just five years. Research on European facilities shows that many facilities failed due to low revenue or high cost of preparing feedstock. Additionally, when facilities need repairs, the waste must be transported elsewhere. The chart below shows the estimated capital costs of maintaining a facility with a 15 megawatt (MW) output in 2013:

Source: GAIA

However, even with these risks in mind, U.S. Navy Commander Michael Knickerbocker argues that the U.S. military should expand its use of plasma gasification. After the Department of Defense (DOD) permanently closed the Red Hill Bulk Fuel Storage Facility on Oahu, HI, the U.S. Navy was forced to find an alternate fuel source for the Indo-Pacific fleet. The Navy currently operates a Plasma Arc Waste Destruction System onboard Ford-class aircraft carriers, and the Air Force has run a plasma power plant at Hurlburt Field, FL, since 2010. The Hurlburt facility is one of 75 “waste-to-energy” currently in operation in the U.S. as of October, 2023. In Europe, there are currently 400 in operation.

Plasma gasification presents significant risks. We must continue developing and researching plasma technology to minimize risk and cost and maximize energy efficiency. However, the environmental benefits and impact on hazardous waste cannot be overlooked. Countless industries, including the U.S. Armed Forces, currently utilize plasma technology. This indicates it is possible to develop safe, reliable facilities. Rather than being intimidated by the risks, we can continue pushing forward in the plasma technology industry.

Written by Grace Mower, Public Policy Intern

The Alliance for Innovation and Infrastructure (Aii) is an independent, national research and educational organization. An innovative think tank, Aii explores the intersection of economics, law, and public policy in the areas of climate, damage prevention, energy, infrastructure, innovation, technology, and transportation.